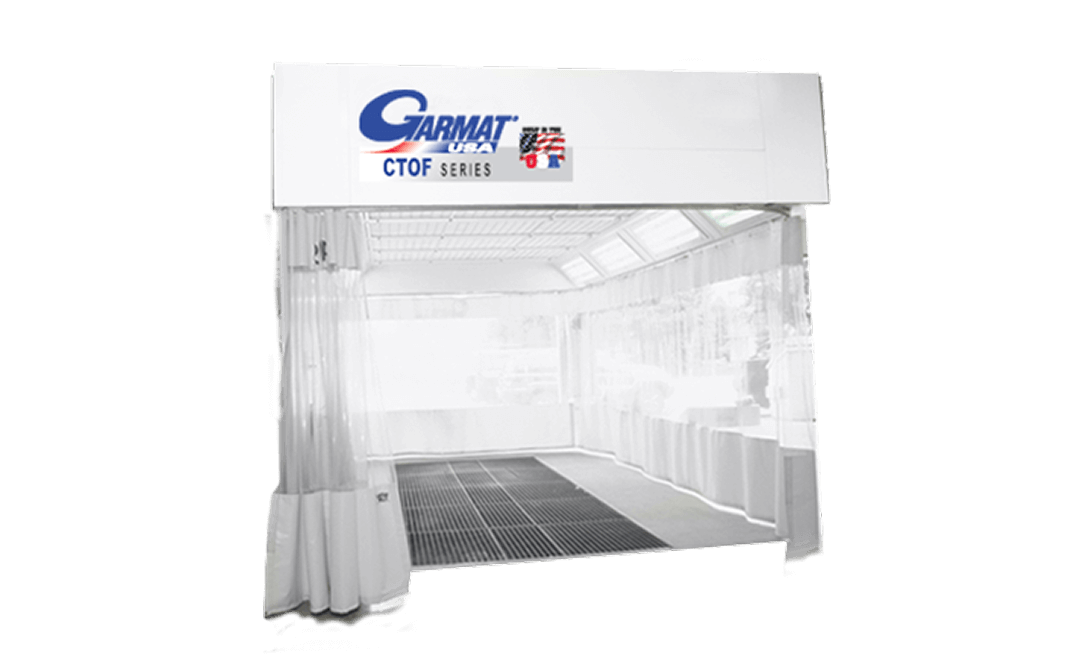

CTOF

Closed Top Open Front Spray Booth

Garmat USA’s CTOF (Closed Top Open Front): The Original Spray Booth-Listed Prep Station. Garmat’s CTOF (Closed Top Open Front) was the first prep station to be officially listed as a paint spray booth, a distinction that sets it apart from standard prep stations. Fully compliant with NFPA 33 spray booth regulations, the CTOF gives you the freedom to Prep, Prime, and Paint in one dedicated area—all without limitations. This helps collision centers stay on schedule and meet production goals more efficiently.

In today’s competitive collision repair market, success depends on minimizing delays and maximizing quality. Garmat CTOFs are engineered to streamline workflow and eliminate the paint shop bottleneck, resulting in increased throughput and improved cycle times.

Our CTOF line is available in Single, Dual, and Triple Bay configurations, with flexible airflow options including downdraft and modified downdraft systems.

Need to accommodate larger vehicles? Garmat also offers CTOF paint spray booths with extended roof heights, ideal for transit vans and medium-duty trucks.

.png?ts=1750875892?height=10&fit=crop,smart)

The Highlights

20 ft – Single and Dual Bay Models

Exterior Dimensions:

Single Bay 20’ 4-5/8” L x 11’ 9-3/4” W x 10’ 10” H

Dual Bay 20’ 4-5/8” L x 23’ 7-5/8” W x 10’ 10” H

Light Fixtures:

- Single Bay CTOF – 8 Light Fixtures / 32 Fluorescent Light Tubes

- Dual Bay CTOF - 16 Light Fixtures / 64 Fluorescent Light Tubes

- Interior accessible light fixtures for easy serviceability

- Upgraded Side-wall light packages available

- 6 and 8 Tube Light Fixture upgrades available

Exhaust Configuration:

- Semi-Downdraft, Downdraft, and Crossflow

- Downdraft models come in a choice of single or three row pit designs

Operations and Controls:

Heated Models- Dual Inlet Reverse Incline Fan featuring Airfoil Blades on Supply and Exhaust

- (2) 10 HP High Efficiency Motors

- Choice of 1.0 or 1.5 MBTU Direct fired heater with fast temperature rise, features Aluminum and Stainless Steel Burner construction

- HMI Touchscreen Panel – State of the Art Controls

- VFD on Exhaust

- Exhaust only Models Available

Curtain Enclosures:

- Top secured heavy duty non-combustible curtain walls with clear view vinyl center panel for unobstructed view

- Fully enclosed, sewn in, galvanized chain in bottom hem for motion reduction and improved appearance

- Glides easily on Steel Track & Rollers

- NFPA and California Fire Marshall approved for fire retardancy

- OSHA approved

24 ft – Single and Dual Bay Models

Exterior Dimensions:

Single Bay – 24’ 3-5/8” L x 11’ 9-3/4” W x 10’ 10” H

Dual Bay – 24’ 3-5/8” L x 23’ 7-5/8” W x 10’ 10” H

Light Fixtures:

- Single Bay - 10 Light Fixtures / 40 Fluorescent Light Tubes

- Dual Bay - 20 Light Fixtures / 80 Fluorescent Light Tubes

- Interior accessible light fixtures for easy serviceability

- Upgraded Side-wall light packages available

- 6 and 8 Tube Light Fixture upgrades available

Exhaust Configuration:

- Semi-Downdraft, Downdraft, and Crossflow

- Downdraft models come in a choice of single or three row pit designs

Operations and Controls:

Heated Models- Dual Inlet Reverse Incline Fan featuring Airfoil Blades on Supply and Exhaust

- (2) 10 HP High Efficiency Motors

- Choice of 1.0 or 1.5 MBTU Direct fired heater with fast temperature rise, features Aluminum and Stainless Steel Burner construction

- HMI Touchscreen Panel – State of the Art Controls

- VFD on Exhaust

- Exhaust only Models Available

Curtain Enclosures:

- Top secured heavy duty non-combustible curtain walls with clear view vinyl center panel for unobstructed view

- Fully enclosed, sewn in, galvanized chain in bottom hem for motion reduction and improved appearance.

- Glides easily on Steel Track & Rollers

- NFPA and California Fire Marshall approved for fire retardancy

- OSHA approved

27 ft – Single and Dual Bay Models

Exterior Dimensions:

Single Bay – 27’ 4-5/8” L x 11’ 9-3/4” W x 10’ 10” H

Dual Bay – 27’ 4-5/8” L x 23’ 7-5/8” W x 10’ 10” H

Light Fixtures:

- Single Bay - 12 Light Fixtures / 48 Fluorescent Light Tubes

- Dual Bay – 24 Light Fixtures / 96 Fluorescent Light Tubes

- Interior accessible light fixtures for easy serviceability

- Upgraded Side-wall light packages available

- 6 and 8 Tube Light Fixture upgrades available

Exhaust Configuration:

- Semi-Downdraft, Downdraft, and Crossflow

- Downdraft models come in a choice of single or three row pit designs

Operations and Controls:

Heated Models- Dual Inlet Reverse Incline Fan featuring Airfoil Blades on Supply and Exhaust

- (2) 10 HP High Efficiency Motors

- Choice of 1.0 or 1.5 MBTU Direct fired heater with fast temperature rise, features Aluminum and Stainless Steel Burner construction

- HMI Touchscreen Panel – State of the Art Controls

- VFD on Exhaust

- Exhaust only Models Available

Curtain Enclosures:

- Top secured heavy duty non-combustible curtain walls with clear view vinyl center panel for unobstructed view

- Fully enclosed, sewn in, galvanized chain in bottom hem for motion reduction and improved appearance.

- Glides easily on Steel Track & Rollers

- NFPA and California Fire Marshall approved for fire retardancy

- OSHA approved

Options and Upgrades

- Accele-Cure® Air Accelerated Drying System

- Blower Systems

- Upgraded Frontals

- Drive Thru Models

- Personnel Access Doors

- Production Enhancing Accessories

- 6 & 8 Tube Light Upgrades

- LED’s and Reflector Options

- Increased Heights

- Door Enclosed Models

- Dual Skin

- Upgraded Mechanicals

- Side Wall Light Packages

What are the Differences?

Garmat® USA’s Closed Top Open Front Spray Booths are constructed of e.g. steel with durable powder coated finish on fascia , and ceiling panels. All non-heated units are equipped with a reverse incline fan and all heated units are equipped with two reverse incline fans. Single non-heated units are standard with 5 Hp Motors. All heated and double units are standard with 10 Hp motors. Both utilize 3 phase intrinsically safe remote control panels. Complete electrical controls are provided (including motor starter, on-off switch and pneumatic controls for recycle damper).

Refer to Features Table on the configuration tab for the equipment that is appropriate to your needs. All units are equipped with listed electrical panels.

Heavy Duty Industrial Curtain Walls:

- Top secured heavy duty non-combustible curtain walls with clear view vinyl center panel for unobstructed view

- Fully enclosed, sewn in, galvanized chain in bottom hem for motion reduction and improved appearance.

- Glides easily on Steel Track & Rollers

- NFPA and California Fire Marshall approved for fire retardancy

- OSHA approved

- Door enclosed models available