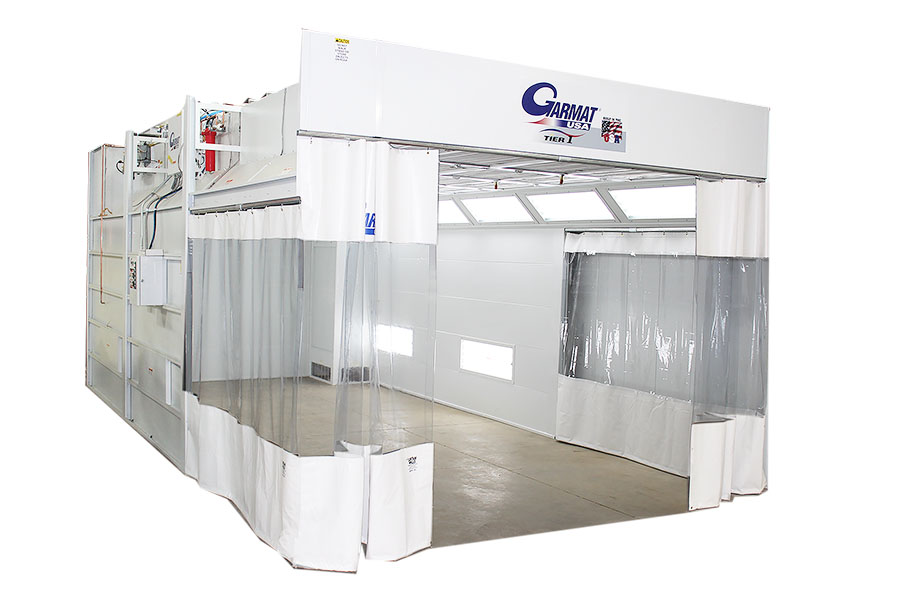

Tier 1 Prep Station

Smart, Cost-Effective Prep Environment

The Tier 1 Preparation Area is an excellent environment for most of your refinish requirements. The heated prep utilizes an integrated mechanical and was designed to fit most budgetary requirements.

.png?ts=1750815867?height=10&fit=crop,smart)

The Highlights

24 ft Modified Downdraft Tier 1 Prep

Exterior:

24 4-3/8” L x 13 6 -5/8” W x 10’10”H

Light fixtures:

- (8) 4- tube light fixtures / 32 LED light tubes

- Add the horizontal sidewall light package for more illumination

- All interior accessible for ease of maintenance

Exhaust Configuration:

- Unlike competing brand of semi downdraft spray booths, the Garmat design pulls the air to the base of the towers, where it is exhausted inside the tower chamber through bag filters.

- Bag filter design provides 54% more useable surface area than competing brands

- Easy access – no grates to remove

- Pitless booth, exhausts through the base of the towers

Operations and Controls:

- Space saving design features a mechanical built into the roof

- Exhaust: 7.5 HP High Efficiency Motors Dual Inlet Reverse Incline Fan featuring Airfoil Blades

- Supply: 7.5 HP High Efficiency Motors with Forward Incline Fans

- 1.0 MBTU Direct fired heater with fast temperature rise, features Aluminum and Stainless Steel Burner construction

- ETL Listed PLC Control Panel which sequences spray and bake mode temperatures settings

- Recycle on Bake

27 ft Modified Downdraft Tier 1 Prep

Exterior:

27 2-1/4” L x 13 6 -5/8” W x 10’10” H

Light fixtures:

- (8) 4- tube light fixtures / 40 LED light tubes

- All interior accessible for ease of maintenance

Exhaust Configuration:

- Unlike competing brand of semi downdraft spray booths, the Garmat design pulls the air to the base of the towers, where it is exhausted inside the tower chamber through bag filters.

- Bag filter design provides 54% more useable surface area than competing brands

- Easy access – no grates to remove

- Pitless booth, exhausts through the base of the towers

Operations and Controls:

- Space saving design features a mechanical built into the roof

- Exhaust: 7.5 HP High Efficiency Motors Dual Inlet Reverse Incline Fan featuring Airfoil Blades

- Supply: 7.5 HP High Efficiency Motors with Forward Incline Fans

- 1.0 MBTU Direct fired heater with fast temperature rise, features Aluminum and Stainless Steel Burner construction

- ETL Listed PLC Control Panel which sequences spray and bake mode temperatures settings

- Recycle on Bake

Options and Upgrades

- Downdraft Exhaust Pits

- Accele-Cure® Air Accelerated Drying System

- Blower Systems

- Drive Thru Models

- Personnel Access Doors

- Production Enhancing Accessories

- Side Wall Light Packages

- 6 & 8 Tube Light Upgrades

- Increased Heights

- Extended Lengths