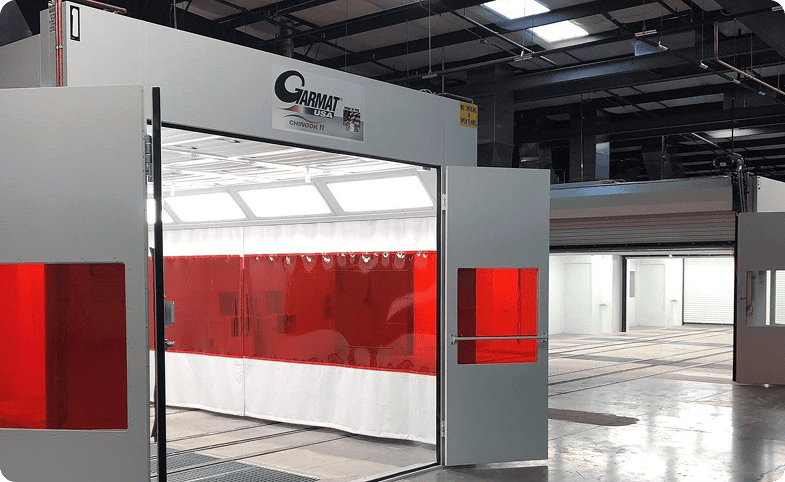

About Garmat USA

Technology · Innovation · Quality · Support

Since 1988, Garmat USA has been redefining innovation in the collision repair industry with precision-engineered paint booths proudly manufactured in the United States. But we’re more than just a paint spray booth provider, we are your total solutions partner.

.jpg?ts=1750866192)

.jpg?ts=1750866295)

Supporting Your Most Critical Asset: The Paint Booth

At Garmat, we understand that the paint booth is the heart of your operation. From design and installation to preventative maintenance and advanced diagnostics, our solutions are built to keep your booth running at peak performance — today and into the future.

Total Paint Booth Solutions – For the Life of Your Equipment

We offer a complete suite of services, including:

- Equipment Sales & Custom Engineering

- Turnkey installation and professional project management

- Preventative Maintenance Programs

- Paint Booth Parts and Filters for more than Garmat Brands

- Break-Fix & Emergency Services

- IoT-Connected Performance Monitoring

Why Choose a Garmat?

With a coast-to-coast combined network of Garmat company divisions, certified distribution partners, and service professionals. Garmat combines national strength with personalized, local service.

Our customers include:

- Independent Collision Centers

- MSOs & OEM-Certified Networks

- Heavy-Duty Truck & Industrial Finishers

- Aerospace, Aviation & Specialty Markets

.jpg?ts=1750866547)

National Support.

Local Expertise.

Garmat® USA paint booths and refinish equipment is built to meet or exceed all applicable codes. NFPA (33, 86, 70, 91 and 101) Standards, National Emission Standard for Hazardous Air Pollutants, 6H (NESHAP Subpart HHHHHH), OSHA Safety and Health Standards (29CFR 1910.107), ETL, IFC, IBC.*

Code Compliance is dependent upon the manner in which the equipment is installed and used. The paint booth and refinish equipment installation is dependent on the local jurisdiction authorities. To ensure compliance it is recommended that the Garmat equipment be installed by a certified Garmat Distributor.

Your Partner in Productivity

In a rapidly evolving industry, Garmat helps you stay ahead through continual innovation, real-time performance insights, and end-to-end support. With Garmat, you’re not just purchasing equipment, you’re getting a partner for life

HEAR FROM OUR CUSTOMERS

Testimonial Videos

.jpg?ts=1750868233)

.jpg?ts=1750868246)

.jpg?ts=1750868246)